In the current economic climate, the bedding industry is facing significant challenges as companies grapple with rising tariffs and supply chain disruptions. Chad Altbaier, CEO of Nevada-based Standard Fiber, which serves as a crucial link between Chinese manufacturers and American retailers, has described these times as the most difficult of his career. With tariffs on imports reaching substantial levels, retailers are modifying their orders, leading to uncertainty in supply and pricing in major stores such as Walmart and Target.

| Article Subheadings |

|---|

| 1) Overview of the Bedding Industry’s Crisis |

| 2) Tariffs and Their Impact on Orders |

| 3) Domestic Challenges in Textile Production |

| 4) Strategic Moves to Mitigate Losses |

| 5) Future Outlook for the Market |

Overview of the Bedding Industry’s Crisis

Across America, bedding companies are struggling to adapt to the current market conditions influenced by international trade policies and a fluctuating economy. Chad Altbaier leads Standard Fiber, a company that has positioned itself between Chinese textile producers and well-known retail giants like Walmart and Target. The ongoing disruptions have not only affected supply chains but also resulted in fluctuating product demand and heightened prices, leading to widespread uncertainty in the industry.

Tariffs and Their Impact on Orders

U.S. tariffs imposed on Chinese imports have had a profound effect on the bedding market, causing retailers to reevaluate their purchasing strategies. Earlier this year, tariffs reached a staggering 100%, leading many retailers to cancel orders outright. As the tariffs have now stabilized at 30%, some retailers are rushing to place orders again, driven by the desire to restock essential goods. A deal reached in mid-May provides a temporary solution that will last until mid-August; however, the uncertainty regarding international relations remains a significant concern.

“You can’t walk into a Walmart or a Target or a Costco or a Home Goods and have nothing to sell,” Altbaier noted.

Domestic Challenges in Textile Production

Despite having manufacturing facilities situated in the U.S., Chad Altbaier has emphasized that the company cannot fully shift its production away from Asia due to various limitations. The United States lacks the necessary infrastructure, a skilled workforce, and access to raw materials that have traditionally come from Asian countries.

“We don’t have the infrastructure,” Altbaier stated. “We don’t have the workforce. We don’t have the experience. We don’t have the raw materials here.”

This leaves companies like Standard Fiber in a difficult position, balancing local production capabilities with reliance on overseas suppliers.

Strategic Moves to Mitigate Losses

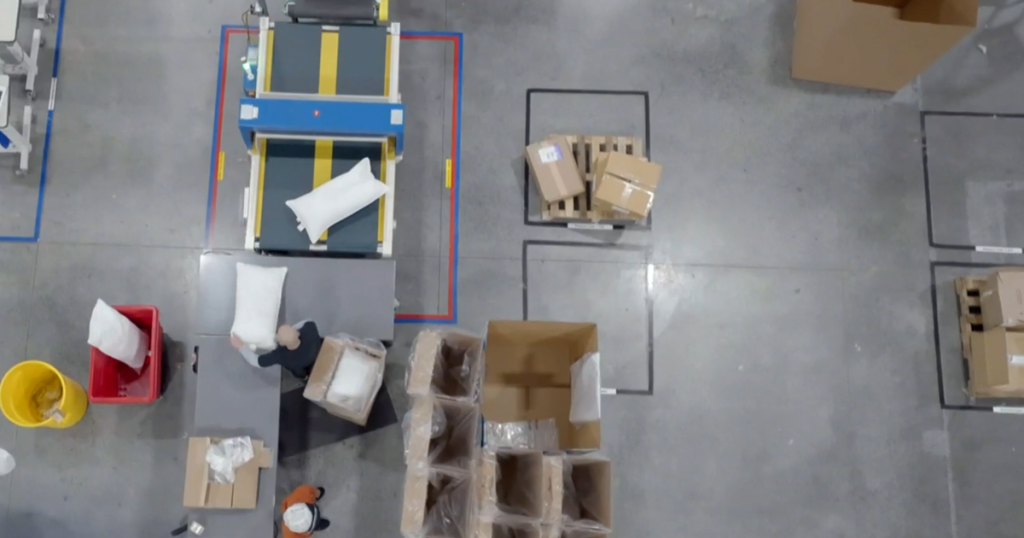

In an attempt to cushion the financial impact of rising costs and reduced demand, Standard Fiber has undertaken strategic shifts in their production process. While some manufacturing has been relocated to other Asian countries, this has not come without its own challenges, as costs are expected to rise significantly. Chad Altbaier indicated that the company’s revenue loss due to tariffs has resulted in hard decisions, including workforce reductions. About 45 out of 250 employees have been laid off as the company attempts to navigate these financially taxing times.

“What keeps me up at night is the not knowing part,” Altbaier expressed.

Future Outlook for the Market

Looking ahead, the bedding industry may face a prolonged period of volatility. A report from the Institute for Supply Management indicated a continuing decline in customer orders, with overall import activity at its lowest in 16 years. Many are attributing this downturn to ongoing tariffs and a general sense of economic uncertainty. As companies adapt to these profound changes, the price of home textiles is poised to rise, further influencing consumer purchasing decisions. Significant concerns remain regarding the long-term sustainability of companies that depend heavily on overseas suppliers for essential materials and production.

“These unprecedented tariff situations are wreaking havoc on the world, not just the U.S.,” Altbaier remarked.

| No. | Key Points |

|---|---|

| 1 | Standard Fiber faces significant challenges due to rising tariffs and economic uncertainties. |

| 2 | Tariffs have compelled retailers to cancel and modify orders, adversely affecting supply chains. |

| 3 | The U.S. lacks the necessary infrastructure to fully transition textile production from Asia. |

| 4 | Some production has shifted to other Asian countries but at a cost, impacting prices further. |

| 5 | The future for the bedding market remains uncertain, with declining orders and rising costs anticipated. |

Summary

The bedding industry, exemplified by the struggles of Standard Fiber, is navigating a landscape shaped by geopolitical tensions and economic concerns. As tariffs on imports continue to fluctuate, the ramifications on production and pricing are becoming increasingly evident. With domestic manufacturing unable to fully replace overseas production, the outlook remains fraught with uncertainty, underscoring the need for strategic adaptation in a competitive market.

Frequently Asked Questions

Question: What challenges is Standard Fiber currently facing?

Standard Fiber is grappling with significant challenges posed by rising tariffs on imports, leading to canceled orders from retailers and workforce reductions due to revenue losses.

Question: Why are tariffs affecting the bedding industry so severely?

Tariffs have increased the cost of imported goods, prompting retailers to adjust their orders and impact the supply chain, contributing to economic uncertainty within the industry.

Question: How is Standard Fiber adapting to production challenges?

The company has relocated some production to other Asian countries; however, this comes with increased costs, and they still face limitations in domestic production capabilities.