In a recent exchange highlighting ongoing tensions between tech giants and political expectations, White House trade advisor Peter Navarro criticized Apple CEO Tim Cook regarding the company’s hesitance to relocate more manufacturing operations from China to the United States. Navarro’s comments underscore the Trump administration’s increasing pressure on Apple to produce its flagship products domestically, a move those in the industry believe is challenging to achieve. As Apple juggles its supply chain and manufacturing strategies amid tariffs and rising costs, the future of where iPhones are made remains a hot topic among analysts and supply chain experts.

| Article Subheadings |

|---|

| 1) Navarro’s Criticism of Apple |

| 2) Trump’s Demands for Domestic Production |

| 3) Challenges of Shifting Production |

| 4) Apple’s Investments in U.S. Manufacturing |

| 5) Industry Experts Weigh In |

Navarro’s Criticism of Apple

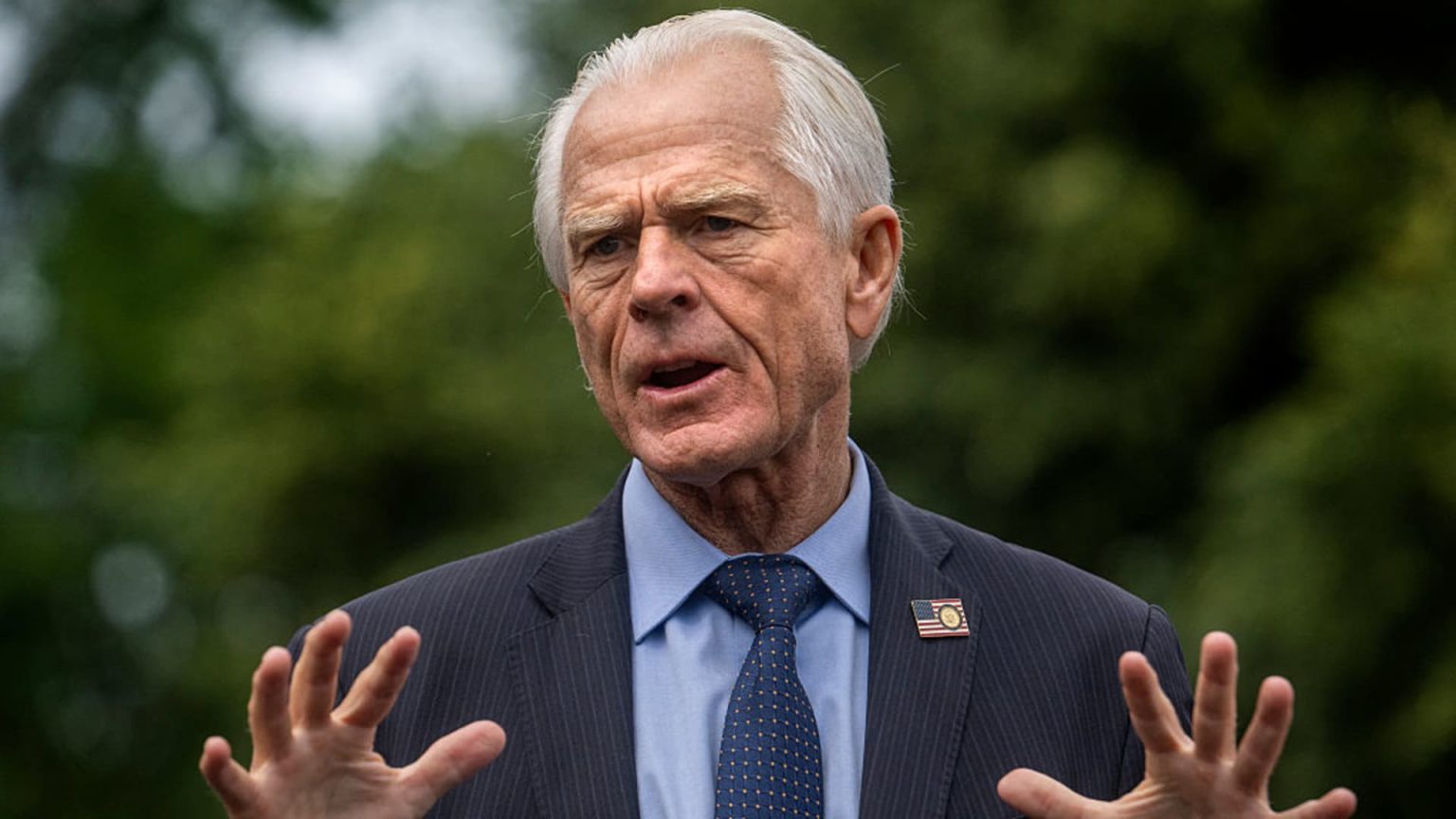

During an interview on CNBC’s “Squawk on the Street,” Peter Navarro expressed frustration over Tim Cook’s slow response to move Apple’s production facilities out of China. Navarro stated,

“Going back to the first Trump term, Tim Cook has continually asked for more time in order to move his factories out of China. I mean it’s the longest-running soap opera in Silicon Valley.”

This critique reflects a broader sentiment among policymakers who have advocated for reshoring manufacturing jobs to the U.S. Navarro’s comments not only indicate a dissatisfaction with Apple’s pace but also represent the increasing scrutiny tech companies are facing amid national and economic security concerns.

Trump’s Demands for Domestic Production

In recent months, President Trump has intensified his calls for Apple to shift its production of the iPhone to the U.S., leveraging high-stakes tariffs to push for change. Trump’s administration has positioned tariffs as a vital tool to combat China’s competitive edge in manufacturing, openly warning that Apple could face a 25% tariff on iPhones manufactured outside U.S. borders. Specifically, Trump has told Cook,

“I don’t want you building in India.”

Such remarks underline a significant political pressure on Apple to comply with the administration’s broader trade policy.

Challenges of Shifting Production

Despite the pressure, industry analysts argue that moving all iPhone production to the U.S. presents formidable logistical and economic challenges. Experts estimate the cost of a U.S.-made iPhone could escalate to as much as $3,500 if all production components were shifted. This would not only impact the pricing strategy for Apple but also might alienate a significant customer base that expects affordable products. Furthermore, the lack of sufficient domestic suppliers capable of meeting Apple’s wide-ranging manufacturing needs exacerbates the feasibility issues. Experts within the supply chain domain suggest that alterations in manufacturing could require overhauls not only in Apple’s production facilities but also in the entire U.S. infrastructure for electronics manufacturing.

Apple’s Investments in U.S. Manufacturing

In a response to both government pressures and market demands, Apple has announced plans to invest significantly in U.S. manufacturing. The company disclosed a $500 billion investment focused, in part, on boosting the assembly of specific products such as AI servers. However, the emphasis on AI over traditional manufacturing raises questions about the company’s commitment to producing iPhones domestically. Although Apple did extend its commitment to assembling the high-end Mac Pro in Texas during Trump’s first term, the scale of labor and resources available in the U.S. remains a crucial barrier against shifting iPhone production.

Industry Experts Weigh In

Amid the ongoing debate about the feasibility of moving production out of China, industry experts have raised critical questions about the practicality of such a shift. Analysts emphasize that advanced manufacturing techniques using artificial intelligence could potentially allow for diversified production sites; however, widespread implementation will take time. Experts suggest that rather than completely uprooting production, Apple might take a more hybrid approach by balancing production in the U.S. and other countries such as India. In this evolving landscape, industry dynamics, labor force availability, and technology improvements will play pivotal roles in shaping Apple’s manufacturing decisions moving forward.

| No. | Key Points |

|---|---|

| 1 | Peter Navarro criticizes Tim Cook for delays in shifting Apple production out of China. |

| 2 | Trump’s administration pressures Apple to relocate iPhone production to the U.S. amid high tariffs. |

| 3 | Shifting iPhone production entirely to the U.S. could raise costs significantly. |

| 4 | Apple plans a $500 billion investment in U.S. manufacturing but focuses on AI over iPhones. |

| 5 | Industry experts suggest a hybrid production approach for Apple might be more feasible. |

Summary

The ongoing discussion about Apple’s manufacturing strategies amid heightened political pressure reflects broader trends in globalization and domestic manufacturing policies. As Navarro’s criticisms and Trump’s demands suggest, large tech companies face increased scrutiny and demands from policymakers to reassess their international supply chains. The challenges of relocating production are complex, involving not only economic factors but also strategic considerations about future growth and technological development. How Apple navigates this landscape will be pivotal in determining its operational trajectory moving forward.

Frequently Asked Questions

Question: What has Peter Navarro criticized about Apple?

Peter Navarro has criticized Tim Cook for the slow pace at which Apple has moved to shift its manufacturing production out of China, describing it as a prolonged “soap opera.”

Question: What is Trump’s stance on Apple’s production locations?

Trump has pressured Apple to shift iPhone production from overseas to the U.S., warning of significant tariffs for products made outside the country.

Question: Why is it difficult for Apple to relocate production to the U.S.?

Analysts argue that relocating production entirely to the U.S. poses logistical challenges and would likely cause the cost of iPhones to rise significantly, which could negatively impact sales.